Hard Wood Block Board

Price 150.00 INR/ Square Foot

Hard Wood Block Board Specification

- Glue Type

- Urea Formaldehyde, Melamine

- Usage

- Indoor, Furniture, Decoration, Flooring, Wall panel

- Back

- Okoume

- Face

- OKOUME

- Feature

- Strong screw holding, Moisture Proof, Alkaline Resistant, Environmental Friendly, Wear Resistant

- Grade

- First Class

- Glue

- Urea Formaldehyde

Hard Wood Block Board Trade Information

- Minimum Order Quantity

- 1000 Square Foots

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1000 Square Foots Per Week

- Delivery Time

- 10 Days

- Sample Available

- No

- Main Domestic Market

- All India

About Hard Wood Block Board

A Hardwood Block Board is a type of engineered wood panel similar to plywood but with a core made of solid hardwood strips (battens) laid edge to edge. These hardwood strips, typically around 25mm wide, are bonded together with adhesive and then sandwiched between one or more layers of hardwood veneers on both faces. The entire assembly is pressed under high pressure and sometimes heat to create a strong and stable board.

Here's a breakdown of the definition:

- Core Material: The central layer consists of solid strips of hardwood, such as oak, maple, or birch. These strips run parallel to each other.

- Veneers: The core is covered on both sides with thin sheets (veneers) of hardwood. These veneers are usually oriented with their grain direction perpendicular to the core strips for added strength and stability, similar to plywood construction.

- Bonding: Adhesives, often urea-formaldehyde or phenol-formaldehyde depending on the intended use (interior or exterior), are used to bond the core strips together and to adhere the veneers to the core.

- Thickness: Hardwood block boards come in various thicknesses, typically ranging from about 12mm to 50mm.

- Strength and Stability: The hardwood core provides significant strength and rigidity, making the board resistant to bending and warping, especially in longer lengths.

- Screw Holding Capacity: Hardwood block boards generally have excellent screw-holding capacity due to the solid hardwood core.

- Weight: Compared to softwood block boards, hardwood block boards tend to be heavier and denser due to the nature of the wood used in the core.

- Cost: Hardwood block boards are typically more expensive than softwood block boards due to the higher cost of hardwood timber.

Key characteristics of Hardwood Block Board:

- High Strength and Durability: The use of hardwood in the core and as veneers results in a strong and long-lasting board suitable for load-bearing applications.

- Excellent Screw Holding: The dense hardwood core provides a strong grip for screws and fasteners.

- Resistance to Warping and Twisting: The construction with a solid strip core and cross-layered veneers minimizes the tendency to warp or twist.

- Good Dimensional Stability: Hardwood is less prone to expansion and contraction due to changes in humidity compared to some softwoods.

- Smooth Surface Finish: The hardwood veneers provide a smooth surface that is suitable for various finishes like painting, staining, or laminating.

Common Uses of Hardwood Block Board:

Due to their strength and stability, hardwood block boards are used in applications where these properties are crucial, such as:

- High-end Furniture: For making sturdy and durable furniture like tables, benches, cabinets, and shelves.

- Doors and Door Frames: Providing a solid and warp-resistant core for doors and strong frames.

- Partitions: Creating stable and sound-insulating partition walls.

- Paneling: For wall and ceiling paneling where a strong and stable substrate is needed.

- Heavy Worktops: Ideal for kitchen countertops and work surfaces that require strength and durability.

- Load-bearing Structures: In some construction applications where the board needs to support weight.

In essence, Hardwood Block Board is a premium engineered wood product that offers superior strength, stability, and screw-holding capabilities due to its hardwood core and veneers, making it suitable for demanding interior and some structural applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wooden Plywood Category

Pine Block Board

Price 150 INR / Square Foot

Minimum Order Quantity : 250 Square Foots

Usage : Indoor, Furniture, Decoration, Flooring, Wall panel

Glue : E1

Thickness : Different Available Millimeter (mm)

Formaldehyde Emission Standards : E4

ALTERNATE PLYWOOD ( AKM GOLD)

Price 150.00 INR / Square Foot

Minimum Order Quantity : 1000 Square Foots

Usage : Indoor, construction, Furniture, Decoration, Flooring, Wall panel

Glue : Urea Formaldehyde

Thickness : Different Available Millimeter (mm)

Formaldehyde Emission Standards : E4

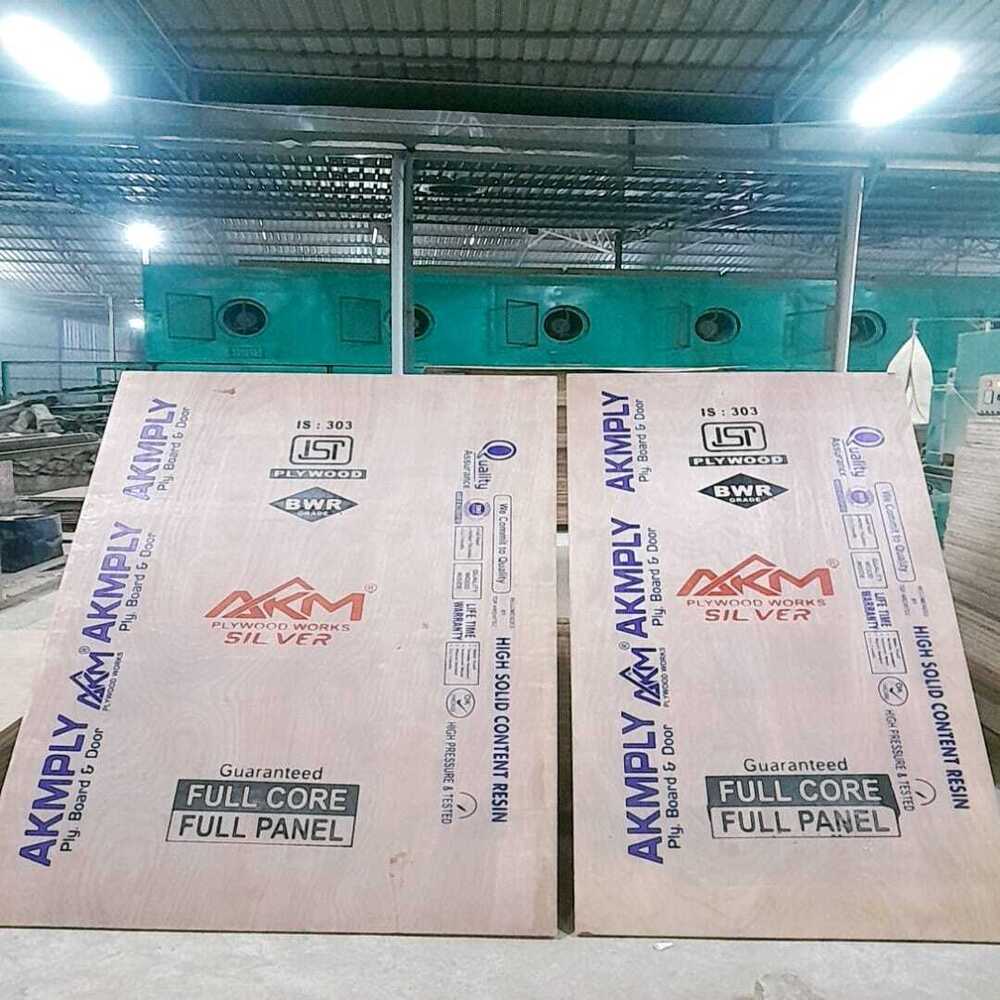

Super MR Plywood ( AKM SILVER )

Price 150.00 INR / Square Foot

Minimum Order Quantity : 1000 Square Foots

Usage : Indoor

Glue : WBP

Thickness : Different Available Millimeter (mm)

Formaldehyde Emission Standards : E4

Red Core Plywood (AKM PLATINUM)

Price 150.00 INR / Square Foot

Minimum Order Quantity : 500 Square Foots

Usage : Indoor, Furniture, Decoration, Door, Wall panel

Glue : Urea Formaldehyde

Thickness : Different Available Millimeter (mm)

Formaldehyde Emission Standards : E4

Send Inquiry

Send Inquiry